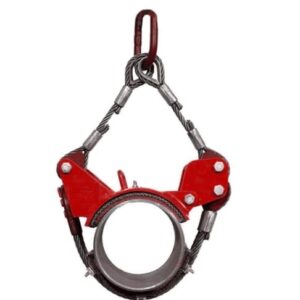

BEAM CLAMP RIGGING ROLLERS:

Product Description Efficiency: Reduces the manual effort required to move heavy loads and cables, increasing operational efficiency.

Safety: Enhances safety by providing secure attachment points and reducing the risk of cable or rope abrasion.

Flexibility: Adaptable to a wide range of applications and environments, providing versatile solutions for rigging challenges.

SPECIFICATION : Material • Body: High-strength steel, alloy steel, or aluminum. • Rollers: Nylon, steel, or other durable, low-friction materials. • Finish: Corrosion-resistant coatings such as zinc plating or powder coating. Load Capacity • Working Load Limit (WLL): The maximum load the clamp and roller assembly can safely handle, usually specified in tons or kilograms (e.g., 1 ton, 2 tons, 5 tons). Safety Factor: Often includes a safety factor (e.g., 5:1) indicating the designed margin of safety beyond the WLL. Beam Compatibility • Beam Width Range: The range of beam flange widths the clamp can accommodate, typically specified in inches or millimeters (e.g., 3 inches to 12 inches, 75 mm to 300 mm).

Adjustment Mechanism: Type of adjustment mechanism, such as screw or bolt adjustments, to secure the clamp to different beam widths. Dimensions

Overall Dimensions: Length, width, and height of the clamp and roller assembly.

Roller Diameter: Diameter of the rollers, which affects the ease of cable or rope movement.

Throat Depth: Distance from the beam flange to the center of the roller, affecting how the load is distributed.

Unit Weight: The weight of the beam clamp rigging roller, important for ease of handling and installation.

Roller Specifications • Material: Type of material used for the rollers. • Bearing Type: Type of bearings used in the rollers (e.g., sealed ball bearings) to ensure smooth operation. • Number of Rollers: Single or multiple rollers, depending on the design. Safety Features • Locking Mechanism: Type of locking mechanism to secure the clamp to the beam (e.g., safety pins, bolts). • Compliance: Certifications and compliance with safety standards such as ANSI, OSHA, or other relevant regulations. Environmental Resistance • Temperature Range: Operating temperature range, indicating suitability for extreme hot or cold environments. • Corrosion Resistance: Level of resistance to environmental factors such as moisture, chemicals, and salt spray.

APPLICATIONS : These specifications are suitable for various applications such as: • Construction Sites: For lifting and guiding heavy materials. • Manufacturing Plants: Used in assembly lines and maintenance operations. • Marine and Offshore: Ideal for use in corrosive marine environments. • Mining Operations: Handles the heavy and rough use in mining.

By carefully considering these specifications, you can ensure that the beam clamp rigging roller you choose will meet the demands of your specific application, providing reliable performance and enhancing safety during lifting and rigging operations.

Reviews

There are no reviews yet.