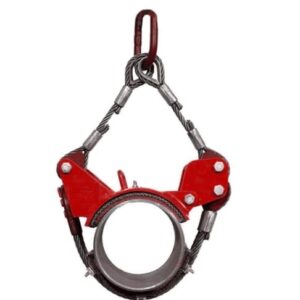

Double Loop Choker Belt involves two loops made from a durable material such as metal or reinforced fabric, which encircle the pipeline. These loops are designed to hold the pipeline firmly in place, preventing movement and reducing the risk of damage due to vibrations or external forces.

Key Features: 1. Double Loop Design: Provides additional security by ensuring the pipeline is held firmly in place from two points. 2. Choker Mechanism: The choker design allows the belt to tighten around the pipeline, offering a snug and secure fit. 3. Durability: Made from high-strength materials to withstand harsh environments and the weight of the pipeline. 4. Adjustability: Often features adjustable components to accommodate various pipeline sizes and ensure a tight fit.

Applications: • Securing pipelines in fixed positions. • Reducing vibration and movement in pipelines. • Supporting pipelines in vertical or inclined positions. Benefits: • Enhanced safety by preventing pipeline displacement. • Prolonged pipeline life by reducing wear and tear. • Versatility in use with different pipeline sizes and materials. This type of belt is crucial in maintaining the integrity and safety of pipeline systems, especially in challenging operational environments.

The specifications for a pipeline double loop choker belt include the following:

Material: • Belts: High-strength materials such as galvanized steel, stainless steel, or reinforced synthetic fibers. • Loops: Steel or reinforced synthetic materials to ensure durability and high load-bearing capacity.

Dimensions: • Belt Width: Typically ranges from 2 to 6 inches (5 to 15 cm), depending on the pipeline size and load requirements. • Belt Length: Adjustable to fit various pipeline diameters. Commonly available in lengths to fit pipelines from 2 inches to 48 inches in diameter. • Loop Diameter: Sized according to the pipeline diameter, usually in the range of 2 inches to 48 inches. Load Capacity: • Designed to handle specific load ratings, which can range from several hundred pounds to several thousand pounds, depending on the pipeline’s size and the application’s requirements.

Adjustability: • Adjustable Buckles or Fasteners: Allow the belt to be tightened securely around the pipeline. Often includes ratchet mechanisms or heavy-duty buckles. • Length Adjustments: Extra length with adjustable fastening to accommodate various pipeline diameters. Safety Features: • Anti-corrosion Coating: Galvanized or stainless steel to prevent rust and corrosion, especially in outdoor or marine environments. • Heat Resistance: Materials that can withstand high temperatures if the pipeline carries hot fluids or gases. • Vibration Dampening: Some designs include additional materials or structures to absorb vibrations and reduce pipeline stress. Installation: • Ease of Installation: Designed for quick and secure installation, often with minimal tools required. • Compliance: Meets industry standards such as ASTM (American Society for Testing and Materials) or equivalent for safety and performance.